The best air purifiers for 3D printing: why you need one today

Within the past 50 years, the use and popularity of 3D printing has exploded. Nowadays, 3D printers are found in a plethora of settings: elementary schools, universities, small businesses, and residential spaces alike. 3D printing’s growing popularity has led to investigations and studies regarding their effects on indoor air quality, and the results are showing that the 3D printing process releases indoor air pollutants that have adverse effects on health. How are these air pollutants generated? What are the risks? Can an air purifier for 3D printing help? Read on to learn more.

Why 3D printing requires specialised air purification

Three-dimensional (3D) printing is an emerging technology that has many useful applications from industrial to domestic use. But what, exactly, is it? How does it degrade indoor air quality?

What is 3D printing and what are the most common filaments?

3D printing involves the melting and depositing of thermoplastics. These materials are deposited in layers in order to build an object. There are various types of 3D printer ink, also called ‘filament’, but the two most commonly-used types include 1) polylactic acid (PLA) and 2) acrylonitrile butadiene styrene (ABS)1,2.

Polylactic acid (PLA)

PLA is widely considered to be the most popular type of 3D printer filament. Biodegradable (under certain commercial settings, not in a residential composter) and derived from renewable sources like corn, it is easy to print with and doesn’t emit an unpleasant odour like ABS does. It is available in an abundance of colours and styles. It is versatile and useful in creating countless objects but is more brittle than ABS so is less ideal for objects that will be bent, twisted, or dropped. It is thermally unstable3.

Acrylonitrile butadiene styrene (ABS)

ABS is less popular than PLA but is superior when it comes to mechanical properties. It is high-strength, durable, and moderately flexible, but more difficult to print with3. It requires higher printing temperatures than PLA.

The hidden risks of 3D printing emissions

Studies have shown that 3D printing emits both fine particles and volatile organic compounds (VOCs) into the air. Emissions vary between printer brands; filament brands, colour, and style; and extrusion temperature. ABS is more heavily polluting than PLS, but all types of filaments are problematic. Research has shown that 3D printing emits fumes and toxic VOCs including styrene, caprolactam, and ethylbenzene, among others. Concerningly, most of the particle pollution emitted by 3D printers is ultrafine (‘UFPs’ measure less than 0.1 microns in diameter), exposure to which has many adverse impacts on human health2.

Source 4

Indoor air quality and health concerns

Ultrafine particles have been heavily researched and have been shown to play a role in the development and aggravation of countless diseases and conditions. Fine and ultrafine particles are also generated by road traffic, industrial practices, smoke, and other sources.

Particles of this size, when inhaled, wreak havoc on the respiratory system, even for healthy individuals. It is even worse for more vulnerable individuals, particularly those who are already suffering from a respiratory disease or condition like asthma, COPD, or allergies, exposure to fine and ultrafine particles may trigger and aggravate their symptoms. However, the danger does not stop at the respiratory system: fine particles, once deposited in the respiratory tract, enter the bloodstream and travel to other organs of the body including the brain and heart. They have also been shown to damage mitochondria, cause cellular damage and death, and induce inflammation and oxidative stress2,5.

Most studies on the effects of 3D printing have been performed using adults as study participants, but 3D printing emissions’ effects on children is particularly worrisome. Children, alongside pregnant women, the elderly, and immunocompromised individuals, are one of the most vulnerable population groups when it comes to the dangers of indoor air pollution. In recent years, 3D printing has been heavily employed in educational settings for children in classrooms and libraries, spaces that are typically poorly ventilated and confined. Although studies on children have been limited, one 2021 study presented the following findings:

- Total mass deposition of fine particles from 3D printers is highest in children between the ages of 9 and 18

- Mass deposition in the lungs is highest in children aged 3 months to 9 years

- Surface area of deposited particles is highest in 9-year-olds6

Legal, safety, and workplace regulations

In the European Union, UK, and USA, most of the regulations that are in place for 3D printing are for when they are used in the medical sector for the printing of medical devices8. In the EU, a risk assessment must be carried out to ensure health and safety of 3D printers in professional spaces that use them for manufacturing. However, with 3D printers being more and more accessible for individual purposes, it makes it much more difficult to regulate and to enforce safe usage. It is highly recommended that anyone using a 3D printer, whether it be for personal or professional use, installs an air purifier for 3D printing in the space in which they are used to reduce air pollution and exposure to fumes.

The benefits of Eoleaf air purifiers for 3D printing:

-

Quiet yet powerful devices (up to 670 m3/hr)

-

Discreet and elegant design

-

Easy to use (equipped with Automatic mode) and does not require installation or assembly

-

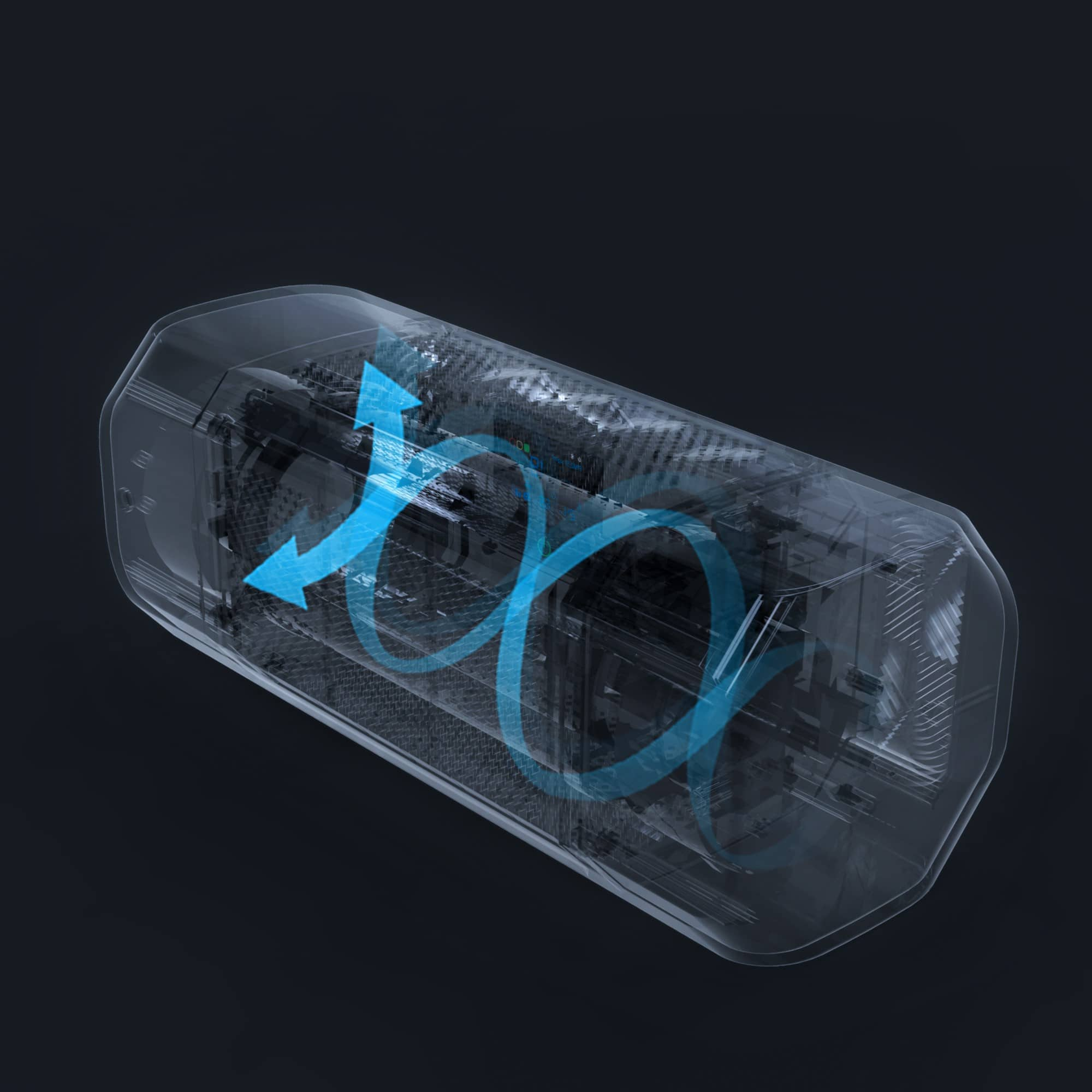

Can be placed anywhere in your space thanks to our 360° technology

-

Real-time air quality data

-

Filters 99.97% of pollutants using unique and innovative filtration technologies

How air purifiers for 3D printers work

Given that 3D printers emit multiple types of indoor air pollution (namely ultrafine particles and volatile organic compounds or VOCs), it is essential that an air purifier for 3D printing be equipped with technologies that will combat these forms of indoor air pollution.

Key filtration technologies explained

Air purifiers for 3D printers and air purifiers in general vary significantly in the filtration technologies that they offer, typically containing one or more technologies. Most air purifiers will come equipped with either a HEPA-certified or HEPA-type filter and an activated carbon filter. Both technologies are essential, but they must be looked at with a critical eye. Other technologies are also very useful in improving indoor air quality that has been degraded by 3D printers.

HEPA filters

In the world of air purification, HEPA filters are a crucial technology in combatting fine and ultrafine particles (PM10, PM2.5, and PM0.1) present in indoor air. It is important to note that brands may claim to be HEPA, but if the filter is not HEPA-certified, its efficacy cannot be guaranteed. HEPA certification means that the filter has been tested for efficiency by a third party. Eoleaf air purifiers, for example, contain only HEPA H13-certified filters as part of its 8-step air purification technology. Be wary of ‘HEPA-type’ filters.

In addition to certification, HEPA filters exist in grades from H10 to H14. Filters that are given the H13/H14 grade are considered to be ‘medical-grade’. All Eoleaf air purifiers offer H13, medical-grade filters and are guaranteed to remove 99.97% of all pollutants down to a size of 0.01 microns in a single pass, ideal for the removal of fine particles produced in 3D printing settings.

HEPA filters remove all of the fine and ultrafine particles emitted by 3D printers, but they also remove allergens like dust, dust mites, pollen, mould spores, pet hair and dander, and more! For 3D printers that are used in urban settings, an air purifier for 3D printing will combat fine particles released by road traffic and industrial practices.

Activated carbon

Unfortunately, HEPA filters do have their limitations. They are only capable of removing fine particle pollution and are unable to remove chemical pollution and fumes (harmful gases and fumes like VOCs) emitted by 3D printers. This is why activated carbon is another essential technology in an air purifier for 3D printing. Activated carbon has been used for its filtration properties for centuries and is extremely effective at removing airborne gaseous and fumes including VOCs, ozone, carbon monoxide, radon, and more.

Simply containing an activated carbon filter does not guarantee that it will combat all of the volatile organic compounds present in your space. Weight matters! An activated carbon filter must be heavy and voluminous: the heavier, the better. The heavier an activated carbon filter, the more chemical fumes it is capable of absorbing. If there is an air purifier model that interests you, before purchasing, make sure to ask the manufacturer of an air purifier for 3D printing for the weight of its activated carbon filter. For transparency, Eoleaf makes all of this information readily available on its website.

Other important technologies

As mentioned above, most air purifiers contain just one or two air purification technologies. Eoleaf air purifiers go the extra mile: our air purifiers contain 8, each of which targets a different form of indoor air pollution. Our 8-step filtration technology offers:

- A pre-filter

- A bamboo filter with an antibacterial coating

- A HEPA H13-certified filter

- An activated carbon filter

- Photocatalysis technologies

- UVC sterilisation technologies

- Ionisation technologies

When it comes to removing pollutants emitted by 3D printers, photocatalysis and ionisation technologies are particularly important. Photocatalysis technologies remove more complex chemical gases and fumes, serving as a complement to the activated carbon filter layer. Ionisation combats ultrafine particles, further protecting your health from the danger they pose.

Additionally, the importance of UVC sterilisation technologies cannot be understated. When an air purifier for 3D printing pulls in all of the air pollutants like chemical fumes that have been released by the 3D printing process, those pollutants are then stored in your air purifier’s filter. The filter becomes a hotbed for germs and the air pollutants that it has accumulated, creating the potential for recontamination when the filter is changed. UVC sterilisation technologies not only remove germs (viruses and bacteria) from your indoor air, but they also sterilise your filter, making it safe for handling during filter replacements.

Airflow and placement considerations

There are some considerations to keep in mind before purchasing an air purifier for 3D printers. First of all, ensure that your device is placed in an area with optimal airflow. This will encourage the air purifier’s optimal air filtration. Avoid placing it in a corner or where it will be obstructed by furniture or other fixtures. Ideally, it should be placed no more than a couple feet or meters from the 3D printer: generally speaking, the closer it is to the source of air pollution, the better.

Another factor to consider is the size of the room or space in which you use the 3D printer. Air purifiers are designed to filter the air in spaces of a maximum size. Eoleaf air purifiers are sized as follows:

- NeoPur 400: spaces of up to 40 m2 (450 sq. ft.)

- TeraPur 600: spaces of up to 80 m2 (850 sq. ft.)

- AltaPur 700: spaces of up to 120 m2 (1300 sq. ft.)

For more information, check out our guide on air purifier sizing here.

Choosing the right air purifier for your 3D printing setting

Your air purifier preferences will likely vary depending upon the setting in which you use your 3D printer. Read on for help in choosing the right air purifier for your 3D printer needs.

For home users and hobbyists

If you are using a 3D printer for personal projects and hobbies, convenience and compact design may be just a couple of details that you will want to prioritise. Seek out air purifiers that provide:

- Quiet operation: check the decibel (dB) rating of the air purifier before purchasing. An air purifier should be powerful yet quiet, never serving as a noisy distraction for you in your living space.

- Compact design: verify that the air purifier won’t take up too much of your valuable space in your home. An air purifier should be compact and fit seamlessly into your printing area.

- Ease of use: an air purifier should always be simple and straightforward to use. Filter replacement should be easy to perform, and in general, there should be minimal maintenance required.

For professionals and industrial use

When using an air purifier for 3D printing in industrial and professional settings, the requirements are a bit different with emphasis more heavily placed on performance and durability. An air purifier for these settings should offer:

- High CADR (Clean Air Delivery Rate): this is an industry standard that specifies how quickly an air purifier can replace all of the air in a room or space. The higher the CADR, the more efficient the device. Professional settings are often larger and print more frequently, so a higher CADR is important in order to manage the emissions generated.

- Long filter lifespan: the need to perform frequent filter changes can be both costly and cumbersome. Search for an air purifier that has durable filters designed for extended use.

- Robust build quality: durability is essential for an air purifier in just about any industrial setting. Models that can withstand constant operation and wear and tear are ideal.

Key selection criteria to compare models

Whether you are an individual or professional, the following criteria are fundamental to consider when seeking out an air purifier:

- Filtration efficiency: perhaps the most important factor to consider when purchasing an air purifier for 3D printers, make sure that the device is capable of capturing both ultrafine particles (HEPA-certified filters and ionisation) and absorbing harmful volatile organic compounds (VOCs) (activated carbon filters and photocatalysis).

- Maintenance: durable filters are important for both budget and maintenance ease. Low-quality filters require changing every three months which significantly increases your maintenance budget. High-quality filters, like those used in Eoleaf air purifiers, only require replacing once a year.

- Energy consumption: an air purifier for 3D printing will likely be running continuously and for extended periods. Find a device that is energy efficient.

- Smart features: more modern air purifiers will offer smart features that make your life and indoor air quality tracking significantly easier. Automatic mode, Night mode, voice commands, hands-free gesture control, smart sensors, Wi-Fi compatibility, and app control are just a few examples - Eoleaf devices contain all of these!

NeoPur 400 air purifier

40 m² (450 sq ft) coverage area - Smart & Connected

TeraPur 600 air purifier

80 m² (850 sq ft) coverage area - Ultimate all-in-one

AltaPur 700 air purifier

120 m² (1300 sq ft) coverage area - Professional model

Why Eoleaf air purifiers are ideal for 3D printing

Eoleaf air purifiers stand out as some of the best air purifiers for 3D printers on the market for both homes and professionals. Thanks to their scientific, modern design, they serve as an excellent solution to indoor air pollution generated by 3D printing.

Advanced multi-layer filtration systems

Eoleaf air purifiers are the only air purifiers on the market to offer an 8-step filtration technology. Our 8-stage approach makes it possible to remove all types of air pollution found in your indoor air. Our devices remove fine and ultrafine particles emitted by 3D printers and effectively combat VOCs and harmful fumes. Regardless of the type of filament you use during the printing process, the high performance of Eoleaf air purifiers protects your health.

Designed for both home and pro environments

We understand that the needs of 3D printing enthusiasts and professionals are diverse. Eoleaf offers multiple models of air purifier for 3D printing, each tailored for various coverage areas and room sizes. Our devices are all powerful yet quiet, even at higher fan speeds. They are, as a result, suitable for any setting in which 3D printers are used: homes, workshops, open-plan office spaces, industrial settings, and educational settings, to name a few.

For professionals, our models are scalable, so whether you have just a single desktop 3D printer in your professional space or a fleet of 3D printers, our devices are designed to purify the air in the entirety of your space and keep you safe from their emissions.

Furthermore, Eoleaf air purifiers all come equipped with smart air quality sensors! These provide you with real-time feedback on your indoor air quality. Automatic mode, available on all of our devices, makes it so that the device automatically adjusts its fan speed when it detects new air pollutants. It then returns to its lowest fan speed once the pollutants have been filtered. This optimises both performance and energy efficiency.

The Eoleaf difference

Now that you better understand the air purification needs linked to 3D printing, you can choose an air purifier for 3D printers that protects you from the dangers their emissions pose to your health. Choose Eoleaf for the most comprehensive air purification on the market. For questions regarding your needs, reach out to the Eoleaf team of air purification experts. Our human - never AI - representatives are here and eager to help you enhance your indoor air quality!

Resources

1 Environmental Protection Agency. (2021, June 15). EPA Researchers Continue to Study the Emissions of 3D Printers. EPA. https://www.epa.gov/sciencematters/epa-researchers-continue-study-emissions-3d-printers

2 Zhang, Q., Pardo, M., Rudich, Y., Kaplan-Ashiri, I., Wong, J. P., Davis, A. Y., Black, M. S., & Weber, R. J. (2019). Chemical composition and toxicity of particles emitted from a consumer-level 3D printer using various materials. Environmental Science & Technology, 53(20), 12054–12061. https://doi.org/10.1021/acs.est.9b04168

3 The complete overview of 3D printer filament types. All3DP. (2024, July 17). https://all3dp.com/1/3d-printer-filament-types-3d-printing-3d-filament/

4 3D printing fumes & Air Quality – A Practical Guide. All3DP Pro. (2024, November 14). https://all3dp.com/1/3d-printing-emissions-air-quality/

5 Oberdörster G, Oberdörster E, Oberdörster J. Nanotoxicology: an emerging discipline evolving from studies of ultrafine particles. Environ Health Perspect. 2005 Jul;113(7):823-39. doi: 10.1289/ehp.7339. Erratum in: Environ Health Perspect. 2010 Sep;118(9):A380. PMID: 16002369; PMCID: PMC1257642.

6 Byrley, P., Boyes, W. K., Rogers, K., & Jarabek, A. M. (2021). 3D printer particle emissions: Translation to internal dose in adults and children. Journal of Aerosol Science, 154, 105765. https://doi.org/10.1016/j.jaerosci.2021.105765

7 Conformity assessment procedures for 3D printing and 3D printed products to be used in a medical context for COVID-1. European Commission Public Health. (n.d.). https://health.ec.europa.eu/document/download/000cf966-c81e-41d7-a452-1b2d4ce17230_en?filename=md_mdcg_qa_3d_ppp_covid-19_en.pdf

8 Bhise, M. G., Patel, L., & Patel, K. (2024). 3D Printed Medical Devices: Regulatory Standards and Technological Advancements in the USA, Canada and Singapore-A Cross-National Study. International Journal of Pharmaceutical Investigation, 14(3), 888–902. https://doi.org/10.5530/ijpi.14.3.99

Eoleaf's range of air purifiers

NeoPur 400 air purifier

40 m² (450 sq ft) coverage area - Smart & Connected

TeraPur 600 air purifier

80 m² (850 sq ft) coverage area - Ultimate all-in-one

AltaPur 700 air purifier

120 m² (1300 sq ft) coverage area - Professional model

PurCar air purifier

HEPA H13 Filter & Ioniser - For all vehicles